03

2017

-

01

Comprehensive understanding of lean production

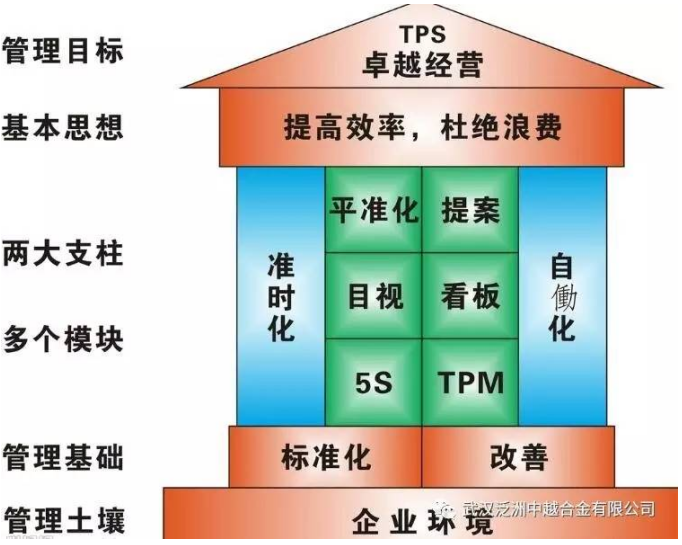

What is Lean Production

Lean production (Lean Production), also known as sophisticated production, in which "fine" means sophisticated, precise, exquisite; "benefit" means benefits, benefits and so on. Lean production is timely manufacturing, eliminate failure, eliminate all waste, to zero defects, zero inventory march. It was proposed by the Massachusetts Institute of Technology in a research project called "International Automotive Project. After doing a lot of investigation and comparison, they believe that the production method of Toyota Motor Corporation of Japan is a kind of production organization and management method suitable for modern manufacturing enterprises, called lean production, in order to address the shortcomings of the United States mass production method. Lean production combines the advantages of mass production and single-piece production, and strives to achieve low-cost production of multiple varieties and high-quality products in mass production.

Advantages and Significance of Lean Production

Compared with mass production methods, the advantages of lean production methods adopted in Japan are mainly manifested in the following aspects:

1, the required human resources-whether in product development, production system, or other departments of the factory, compared with the mass production mode of the factory, the lower energy is reduced to 1/2;

2, new product development cycle-lower can be reduced to l/2 or 2/3;

3, the production process of the product inventory-lower can be reduced to a large number of production methods under the general level of 1/10;

4, the factory occupied space-lower can be reduced to the use of mass production under the 1/2;

5, finished goods inventory-lower can be reduced to mass production mode under the average inventory level of 1/4;

Lean production method is a thorough pursuit of production rationality, efficiency, flexible production to meet various needs of high-quality products production technology and management technology, its basic principles and many methods, the manufacturing industry has a positive significance. The core of lean production, that is, the basic idea of production planning and control and inventory management, also plays an important role in enriching and developing modern production management theory.

Lean Production Core

1, the pursuit of zero inventory

Lean production is a kind of pursuit of no inventory production, or make the inventory to a very small production system, for which a series of specific methods including "Kanban" have been developed, and gradually formed a unique production and management system.

2, the pursuit of rapid response, that is, rapid response to market changes.

In order to quickly respond to changes in the market, lean producers have developed cell production, fixed variable production and other layout and production programming methods.

3. Harmonious unity of the internal and external environment of the enterprise

The key to the success of lean production is to harmoniously unify the internal activities and external market (customer) needs in the development goals of the enterprise.

4. Humanism

Lean production emphasizes the importance of human resources, regards the wisdom and creativity of employees as the precious wealth of the enterprise and the driving force for future development. A, fully respect employees; B. attach importance to training; C. work together.

5, inventory is the "curse"

High inventory is one of the characteristics of mass production. Due to the instability of equipment operation, unreasonable process arrangement, high scrap rate and unbalanced production, the phenomenon of untimely supply often occurs, and inventory is regarded as an essential "buffer". However, lean production believes that inventory is the "scourge" of enterprises. The main reasons are: 1. Inventory increases the cost of operation; 2. Inventory conceals the problems of enterprises.

Other news recommendations

2023/08/05

2020/08/03