Detection range

Directory

DIRECTORY

1. Chemical composition

2. Mechanical properties

3. Hardness test

4. Thermal performance

5. Metallographic analysis

6. Residual stress

7. Failure Analysis

8. Friction and wear test

9. Cleanliness of parts

10. Geometric measurement

11. Water Quality Testing

12. Automobile synchronizer shift durability test

13. Wear test of automobile synchronizer monomer

chemical composition

It has testing equipment such as Spike direct reading spectrometer in Germany, Shimadzu X-ray fluorescence spectrometer in Japan, ICPS plasma atomic emission spectrometer in Japan, flame atomic absorption spectrophotometer, carbon and sulfur meter, ultraviolet spectrophotometer and so on, and can carry out element analysis and standard sample value determination of non-ferrous metals and ferrous metals, such as copper (Cu), zinc (Zn), aluminum (Al), manganese (Mn), iron (Fe), nickel (Ni), lead (Pb), tin (Sn), silicon (Si), cobalt (Co), chromium (Cr), titanium (Ti), zirconium (Zr), molybdenum (Mo), niobium (Nb), carbon (C) sulfur (S), phosphorus (P) and other common elements.

chemical composition

It has an electronic universal testing machine with a high temperature box, which is widely used to test various mechanical properties of materials.

• room temperature stretching

Material elastic modulus, tensile strength, yield and other parameters test.

• Compression/bending, etc.

Material compression strength, bending test, etc.

• high temperature stretching

The elastic modulus, tensile strength, yield and other parameters of the material at a certain temperature are tested.

• Flaring/flattening, etc.

Product flaring, flattening and other functional tests.

Hardness test

HBW10, HBW30 Brinell hardness test

HRA, HRB, HRC Rockwell hardness test; HRN/HRT surface Rockwell hardness test; product hardness rapid detection

HV0.01 ~ HV50 Vickers hardness test; hardness gradient method to detect the effective hardening layer depth of materials; microstructure hardness test

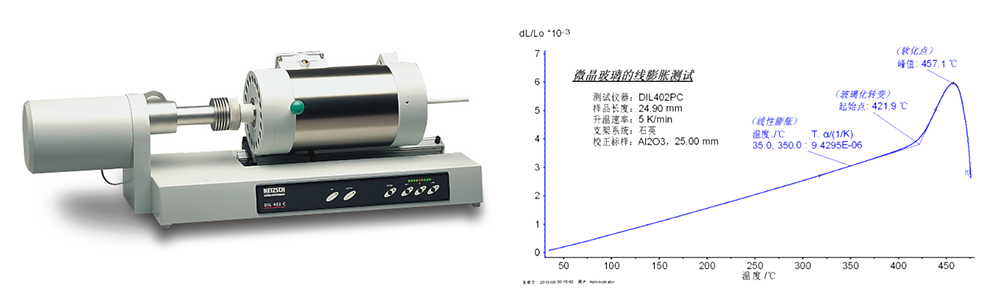

thermal performance

It has German Nechi thermal expansion instrument equipment with an accuracy of 0.125nm. It can be used to determine the thermal expansion coefficient of substances at different temperatures, study the softening process of materials, study the densification and sintering process of materials, determine the glass transition temperature of samples, study the phase transition process, optimize the heat treatment process of materials, etc.

Organization rating: Metallographic organization rating of metal materials.

Phase content analysis: Material specific phase content analysis.

Grain size inspection: material grain size rating.

residual stress

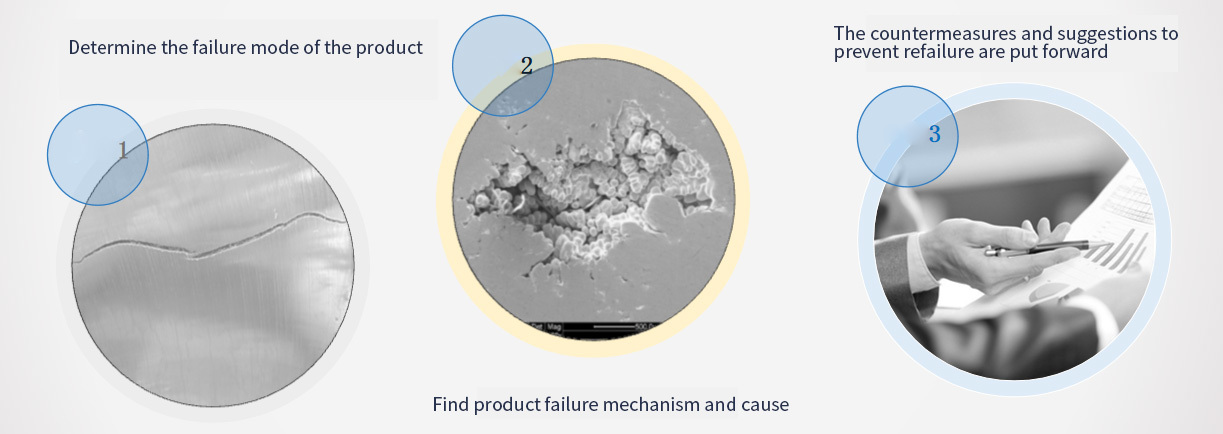

failure analysis

Geometric Dimensions

It has imported advanced high-precision geometric dimension measuring equipment such as German Zeiss three-coordinate, Japanese Keens projector, German Marr roundness meter, Japanese Tokyo precision profiler, roughness meter, etc. It can accurately measure the geometric dimensions of various workpiece surfaces such as three-dimensional and two-dimensional dimensions, roundness, angle, straightness, roughness, etc.

Parts cleanliness

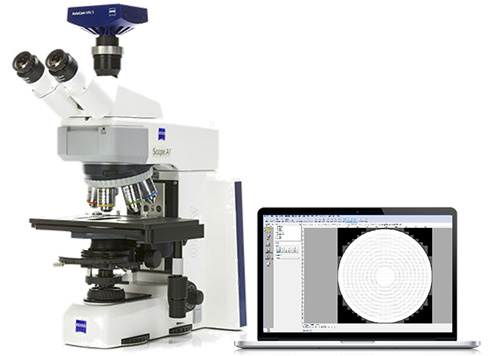

With the German Carl Zeiss professional particle size analysis system, in line with ISO 16232 and VDA 19 automotive parts cleanliness testing standards, for automotive, hydraulic, construction machinery and other fields of parts cleanliness testing.

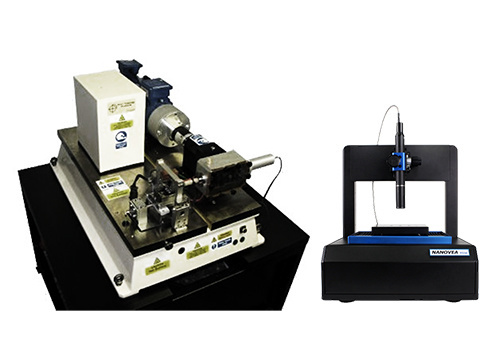

friction and wear test

It has TE 77 long-stroke high-frequency reciprocating friction testing machine and high-precision three-dimensional topography instrument, which is used for dry wear and lubrication friction wear and friction coefficient test of ceramics, metals and composite ceramic materials.

Synchronizer shift durability test

It has a synchronizer shift durability bench testing machine, which can simulate the shift condition of automobile gearbox and evaluate the durability of the synchronizer shift gear ring.

Synchronizer gear ring monomer wear test

It has a bench testing machine for the wear performance of the synchronizer gear ring, which can simulate the operating conditions of the automobile gearbox and evaluate the wear resistance of the synchronizer gear ring.